Rendered by Jecori Owens-Shuler, Design Team Leader

https://www.solarpacknc.com/

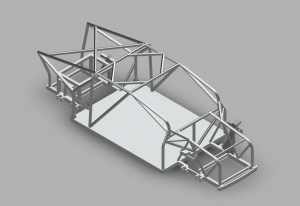

SolarPack, founded in late 2016, pursues a vision of reliable, affordable, practical, and sustainable transportation for the future. Our vehicle, comprised of a AISI Steel 4130/Aluminum 6061 spaceframe, hemp body panels, and polycarbonate windows/windshield, has already turned heads in the solar vehicle community. With the strongest Emrax motor ever seen in the American Solar Challenge, accompanied by never before used Lithium-Titanate batteries, our vehicle should accelerate 0-60MPH in ~6.5 seconds.

As a member of the chassis team, I engaged in the creation of the chassis and body through Fusion360, a sponsor of the team and invaluable asset. The chassis, weighing in at ~1,100 pounds, has exceeded the factor of safety requirements of the American Solar Challenge, and contains built in crush zones along with mounting points for various components. The hemp body was fabricated from wood and medium-density fiberboard molds with the help guidance of OBX Boatworks and Bruce Dietzen, whose hemp-bodied vehicle was featured on the CNBC TV Series ‘Jay Leno’s Garage’.

As the race approaches I have been helping fabricate the body panels, planning and researching window mounting, and participating in the recruitment process through information sessions. We intend on racing in the aforementioned American Solar Challenge, a ~1,780 mile race from Omaha, Nebraska to Bend, Oregon taking place from July 14-22. Beyond that, the team has been invited to the Clinton Global Initiative, taking place October 19-21 at the University of Chicago.

We would appreciate any sponsorships or personal donations. For either, visit the above link or visit https://www.gofundme.com/solarpack.

Chassis Rendering in AutoDesk Fusion360

Welded Chassis, Aluminum 6061 & Steel 4130

Chassis Team Body Panel Fabrication at OBX Boatworks